Biologics are a key driver of future biotech industry growth. The domain is expected to expand at 16-20% per year for next few years, with the upcoming patent expiration of some biologics therapies giving a shot in the arm to manufacturing services. Novel molecules for therapies targeting the oncology segment will also be a key growth driver.

The broadening of biologics development and manufacturing drives increasing demand for viral safety testing and clearance services. These tests are key to obtaining a successful application for clinical trials and commercial licensing of every biologics molecule. Biologics testing services are offered by only a handful of service providers globally and Syngene is proud to be among this group. It is the only provider from India to provide at-par services to biopharmaceutical companies since 2017.

Our facility is GLP-certified by the national GLP compliance monitoring authority from the Government of India, as per the OECD principles of GLP. This certifies our laboratory to be in line with the OECD rules covering countries such as the USA and Japan.

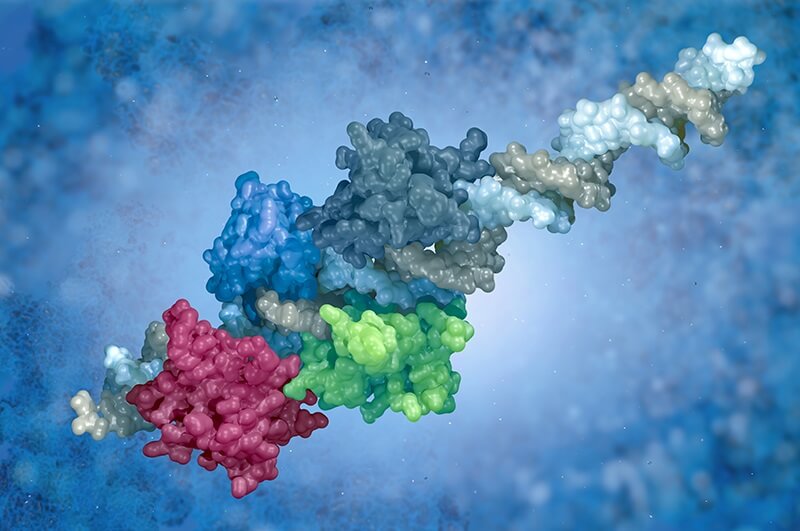

Over the past three years, the Syngene facility has grown from establishing a service capability to enabling virus clearance studies, bulk harvest and research cell bank testing. These services ensure the safety of the drug manufactured in mammalian cell systems like CHO.

Biologics manufacturers need to comply with the regulatory requirements associated with testing of cells expressing the therapeutic drug at cell bank stage, test harvested cells and undertake virus clearance studies for process manufacturing the drug.

The testing and clearance studies ensure that the therapeutic proteins (or drugs) are free of opportunistic pathogens, such as viruses, and assures the robustness of the process to remove viruses which may be introduced unintentionally into the manufacturing environment or process. The orthogonal approach (of testing and clearance evaluation) ensures that patients receive a safe drug.

Quality Approach:

Offering robust quality services with unrelenting customer focus is at the core of everything we do at Syngene. We have invested in the discovery and development and manufacturing phases of the drug pipeline to ensure that we have world class quality systems in place, in line with the global regulatory requirements. Our continuous improvement program includes internal audits and unannounced inspections in addition to client and regulator audits to ensure that quality standards are maintained constantly.

Client audits are an integral part of service delivery at Syngene. They help shape the system as per current regulatory demands. A dedicated team from quality assurance ensure that all studies are inspected in life, reports reviewed and audited before submitting them to clients.

Safety:

Syngene’s inhouse safety programme – Kavach – ensures that every employee understands the organisation’s ethos and approach to safety. We put in place regular safety walkthroughs and conscious safety initiatives to ensure safety is at heart of everything we undertake personally and professionally.

The viral testing services are undertaken in a biosafety level -2 category laboratory. The facility complies with World Health Organisation (WHO) standards for biosafety to handle risk group 2 organisms (viruses and cell lines). The state-of-the-art facility is equipped with adequate controls of engineering and procedures to ensure the safety of people and environment.

Service to Nation in COVID-19 Crisis:

Syngene has extended its support to the nation in its fight against the COVID-19 virus. The Viral Testing Laboratory, along with support from other teams, took the initiative to set up screening of COVID-19 patient samples for SARS-CoV-2 under its CSR program. The laboratory was accredited from NABL, Govt of India and ICMR (Indian Council of Medical Research) to do this work. Scientists, already in our workforce, and conversant with the special skills required to work with infectious samples in Biosafety and Security conditions, provided the impetus and confidence to take up this service initiative as quickly as possible.

Award for Excellence:

Syngene recently won the 4th Annual Asia-Pacific Bioprocessing Excellence Awards 2020 in the category ‘Bioprocessing Excellence in South Asia—Viral Clearance and Safety Testing’. The event was part of the 7th annual #Biologics Manufacturing Asia virtual conference.

Syngene is India’s first and only GLP-certified service provider for Viral Clearance and Safety Testing. With our world-class infrastructure and expertise, we have already delivered over 11+#viral—clearance studies for mammalian-derived Biologics. This has helped our customers complete their regulatory filings on time in regulated markets despite the unprecedented situation arising from the Covid-19 pandemic.

We invite any queries on our viral testing solutions or employment opportunities to be directed to bdc@syngeneintl.com